We've been itching to get on the road for some time, and that day is finally here. We're a lot further along in the renovation than we were on our honeymoon, but we're definitely not done.

We'll get the finishing touches done at some point. I packed a few tools and supplies. And we'll be swinging back to Maryland at some point to do some more work. But for now, we're off.

Our first major stopover is Robert Tremon Park in Ithaca, NY. We learned a hard lesson about staying on truck routes on the way. In case it wasn't obvious, back roads in mountainous regions are generally a bad idea.

To access camping in Robert Tremon, you ford the river at the entrance.

Our campsite is in the middle of a nice sunny field. No hookups, but a water spigot nearby, and that suits us just fine.

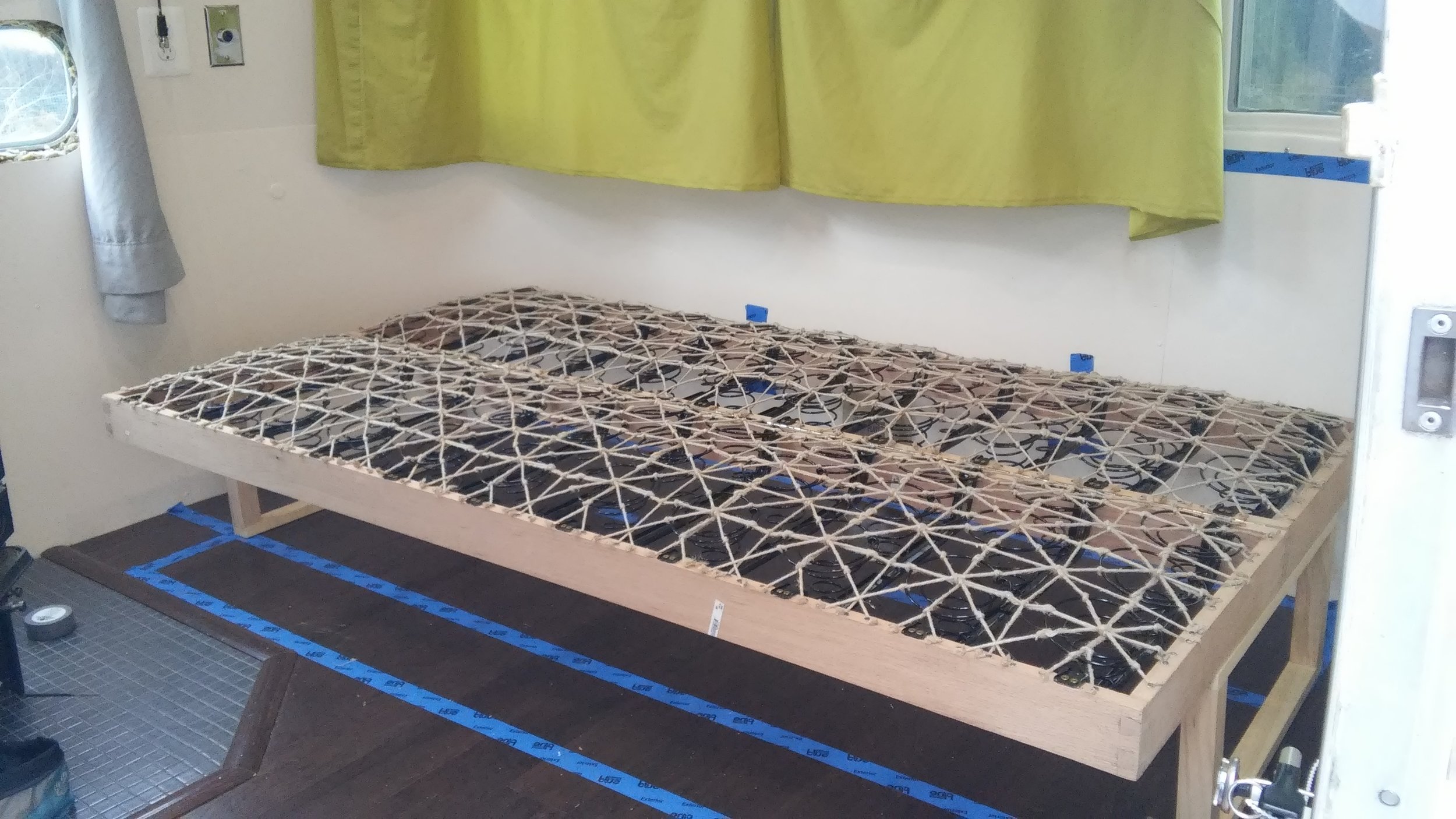

Time to give the solar a workout.

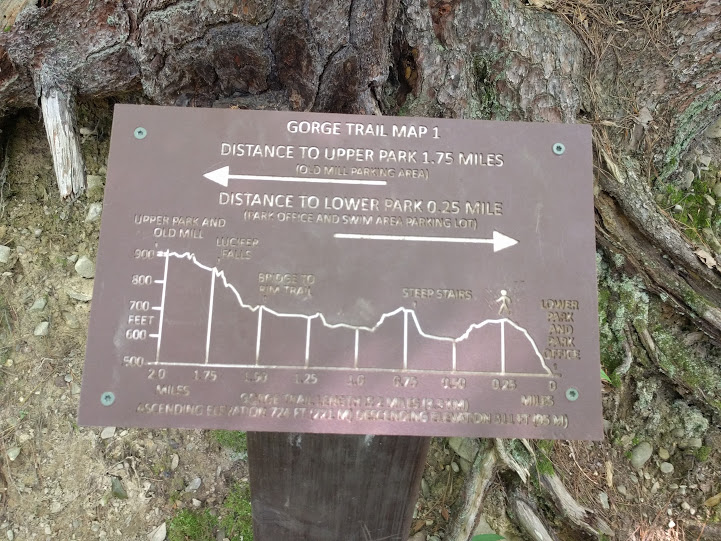

The hike up to Lucifer Falls is difficult to describe. The gorge trail trail from the lower park takes you on a tour of progressively larger waterfalls, each more breathtaking than the last. I'm going to post some pictures, but I almost feel like I shouldn't bother. There's no way any of these pictures come close to showing how beautiful this park is.

Luna enjoyed her hikes immensely.

And if all that wasn't enough to show you how magical of a place this is, can we take a moment to appreciate this violet coral mushroom we found on the rim trail? I promise, this photo is from New York State, not from the bottom of the ocean or the surface of Venus.

Next up, we're headed to Vermont.