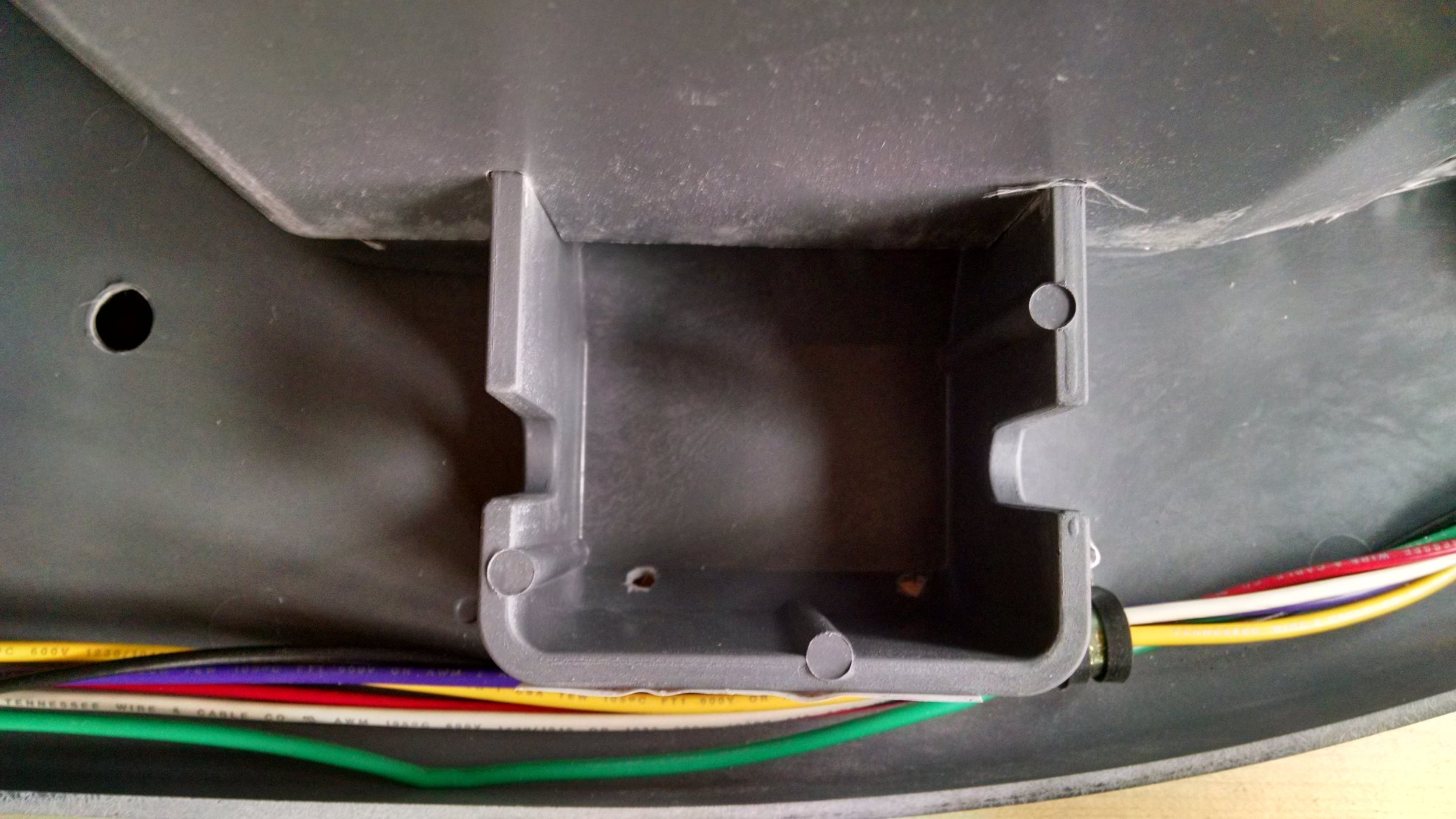

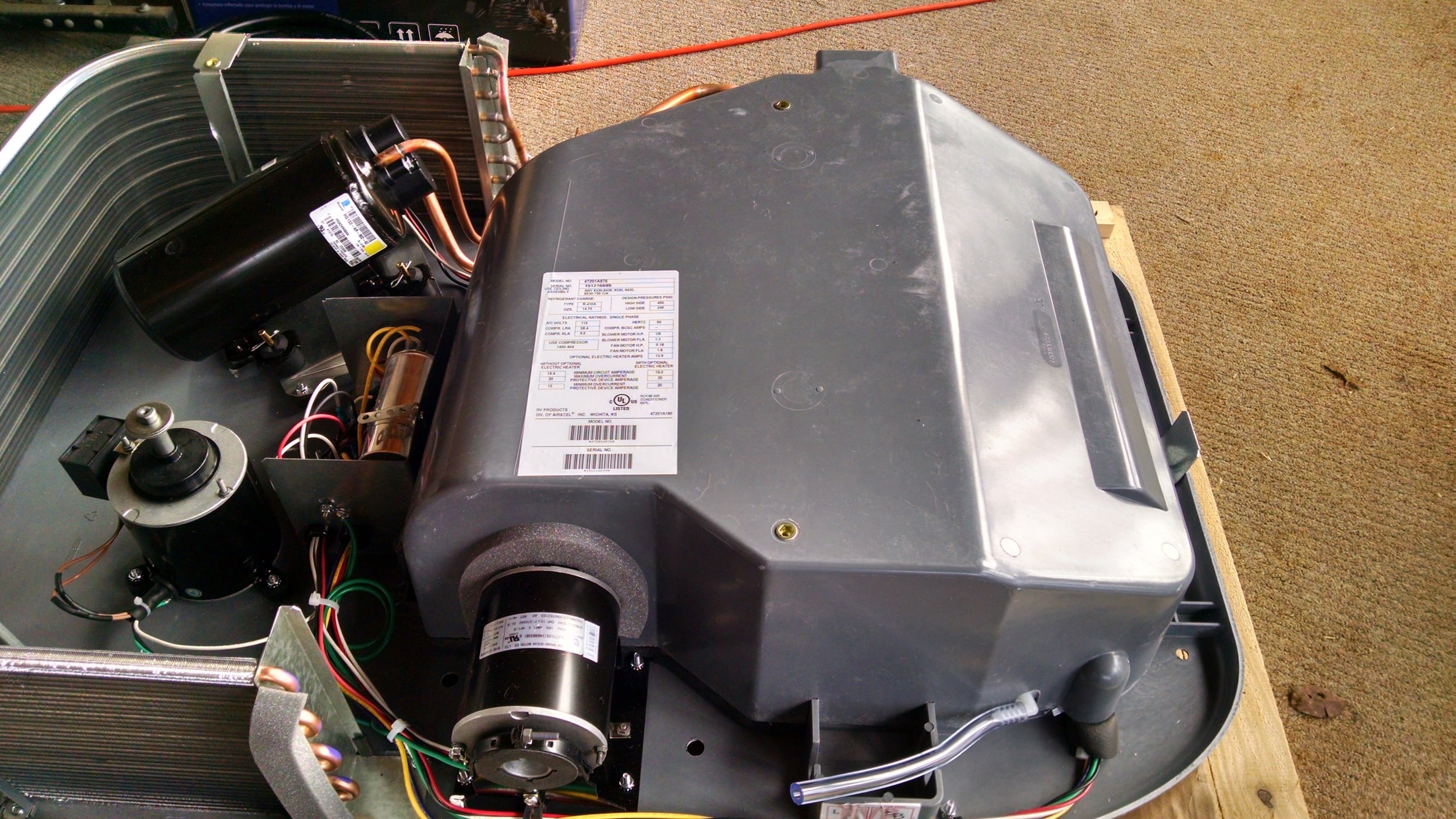

This weekend, I finished completely removing and replacing the AC electric system with armored cable. I rerouted a bunch of DC wires, and added a couple new runs. I also installed the new 30A power inlet on the outside of the trailer.

I installed Reflectix insulation to the top half of the trailer, the part that will get the most sun. This is the same radiant heat barrier that I installed below the subfloor, so it works best if it's facing an air gap. Lots of people use strips of foam insulation to make shims, but I'm not counting on this for my only insulation, so I don't need it to be perfect. I used 1/16" thick double-sided foam tape to mount the Reflectix, but I'm mostly counting on gravity to give me an air space above the shiny stuff. Worst case scenario, in areas where the Rockwool pushes it against the outer skin, I'm still getting an R-1.1 out of the 5/16" layer, which is about the same R-value as 5/16" of Rockwool. I used the same foam tape to insulate the ribs from the interior skin, which should help with heat conducting straight through the ribs. Thanks to blogger Reinergirl and Capn Tom from Airforums for the idea. It took 5 rolls to do all the ribs and hang the Reflectix.

Some of these links are "affiliate links." If you decide to buy something based on our recommendation, it would be nice if you used the direct link from this page so that we can make a small commission for referring you (which doesn't cost you anything extra).

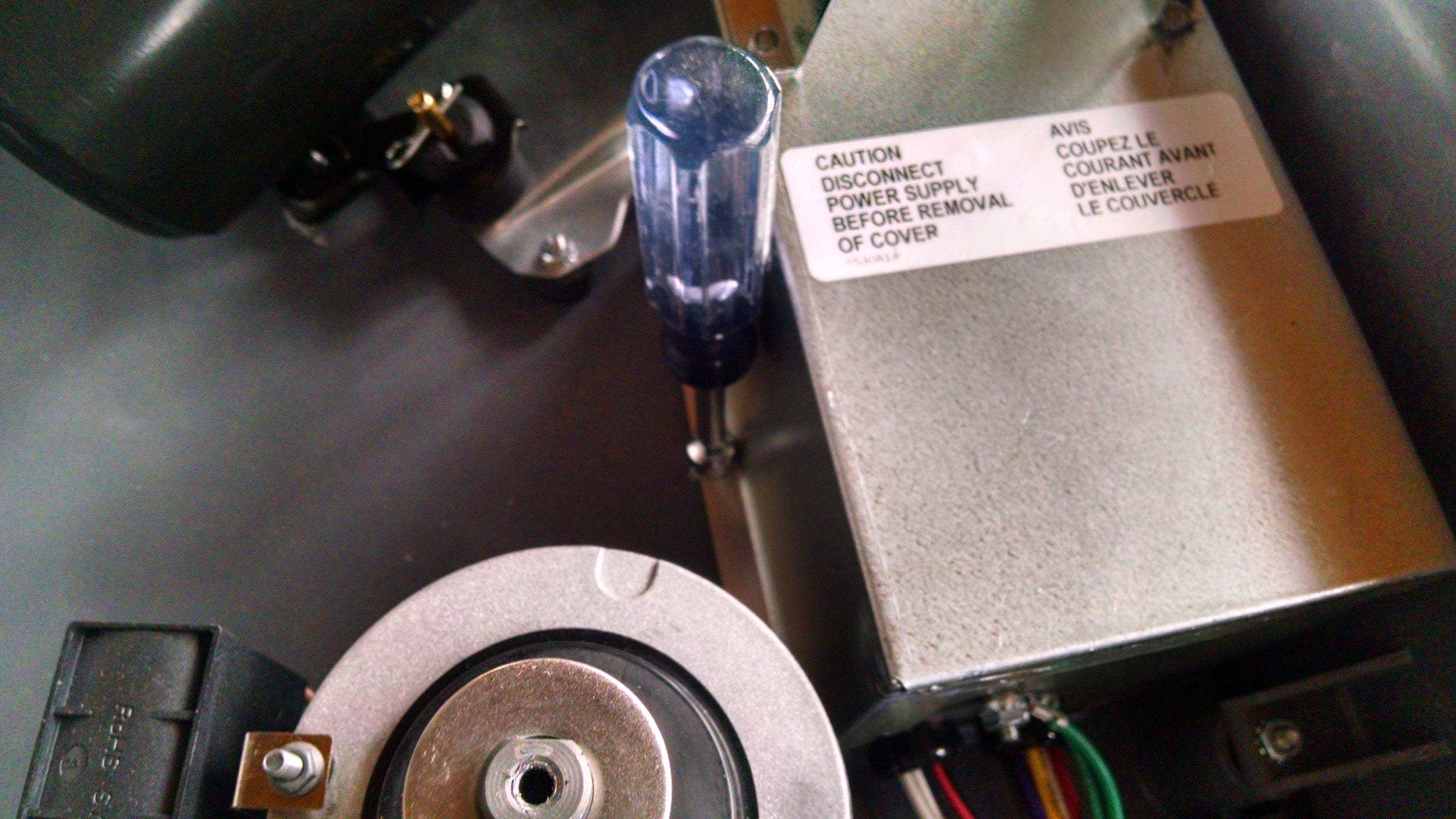

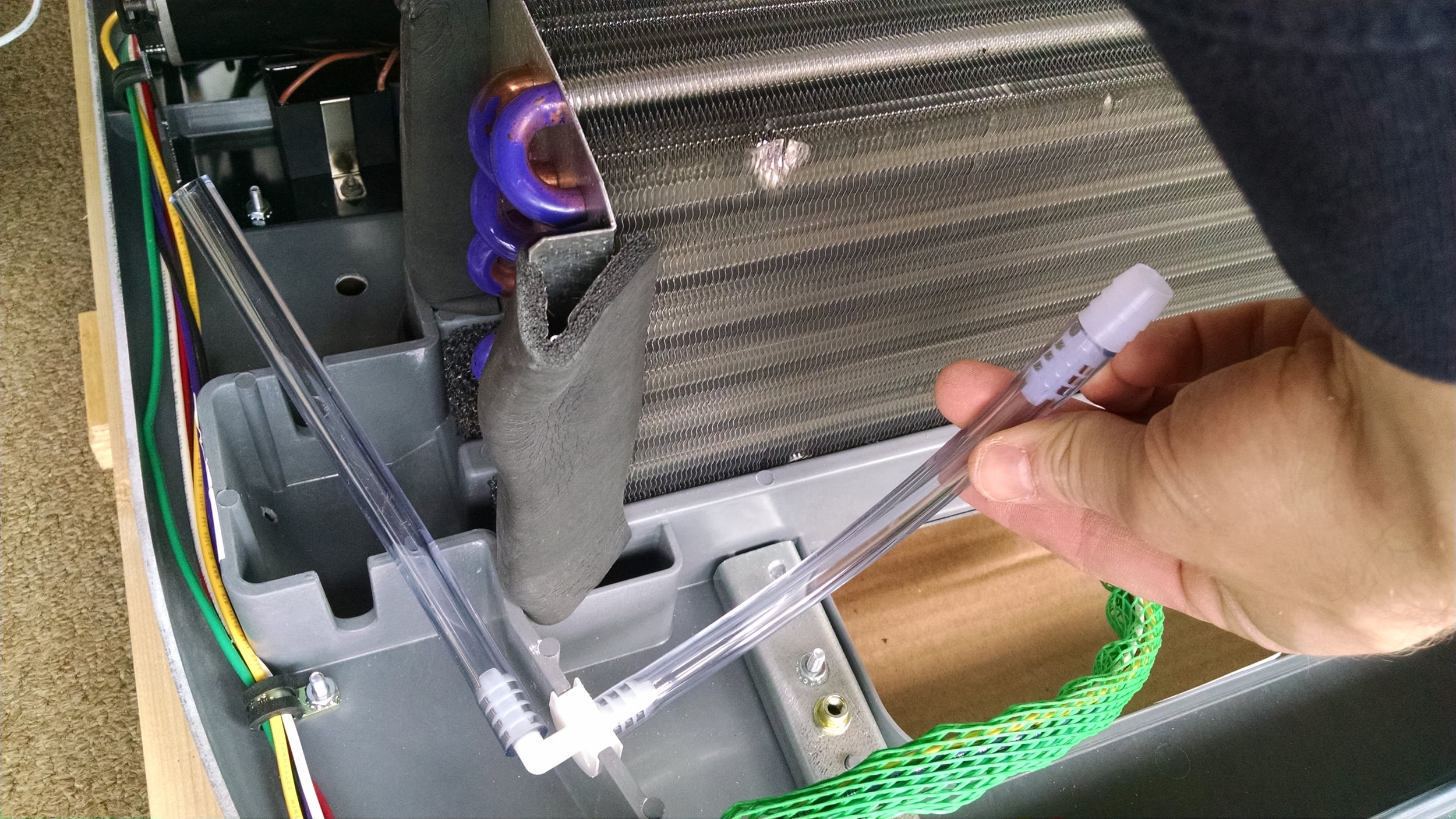

AC ceiling assembly is installed temporarily to provide some heat while I work in 20 degree weather. I have the new 30A inlet wired directly to the air conditioning power supply so I can plug it into the house.

I've read lots of people complaining about how little the heat strip on the Mach 8 cub produces, but it was enough to keep a 27' Airstream with very little insulation and a bunch of holes in the walls comfortable enough to work in jeans and a sweatshirt. When it warmed up to 35 or so outside, I was working in a t-shirt just fine.

Some switches, outlets, odds and ends wired up.

Scare light installed. Boo.

Deadbolt installed. This is mostly to ensure the door doesn't accidentally fly open while we're moving.

Radio antenna. I could make it straight up and down, but I like the jaunty look.

New 7-way trailer plug installed and wired up. Added an extra set of running lights on the sides for visibility. I was hoping I'd be able to wire the DC system to the accessory wire from the truck, but it didn't work. I'll have to either resurrect the Univolt, or find some other way to temporarily power the DC system to test everything before I get the walls closed up.