Some of these links are "affiliate links." If you decide to buy something based on our recommendation, it would be nice if you used the direct link from this page so that we can make a small commission for referring you (which doesn't cost you anything extra).

I'm adding 32 additional gallons of gray water storage so that, combined with the factory 14 gallon gray tank, I have enough gray water storage to match my 45 gallon fresh water storage capacity. I purchased two 16 gallon gray water storage tanks from Vintage Trailer Supply and had them add three fittings -- a 1-1/2" drain/fill on the starboard side aft, a 1/2" low point drain on the bottom at the same corner, and a 1-1/2" vent on the port side top, centered on the edge of the tank.

I was expecting these to arrive in some sort of box. Nope, they just slapped a UPS label on them and chucked them in the truck. No damage, but I thought that was weird.

VTS offers some slightly larger tanks to fit inside the frame of mid-70's Airstreams, but they would hit the gussets (the strips of plywood under the subfloor that support the spot where two pieces of plywood meet), and even if they didn't, there wouldn't be any extra room for supporting them from below.

The tanks themselves weigh very little, but the 16 gallons of water they each hold weighs 134 lbs. The sidewall isn't strong enough to support that weight, so they have to be 100% supported from below. I've seen people try to install these with just a couple straps running underneath, and that's asking for trouble. I chose to support them with 1/2" plywood.

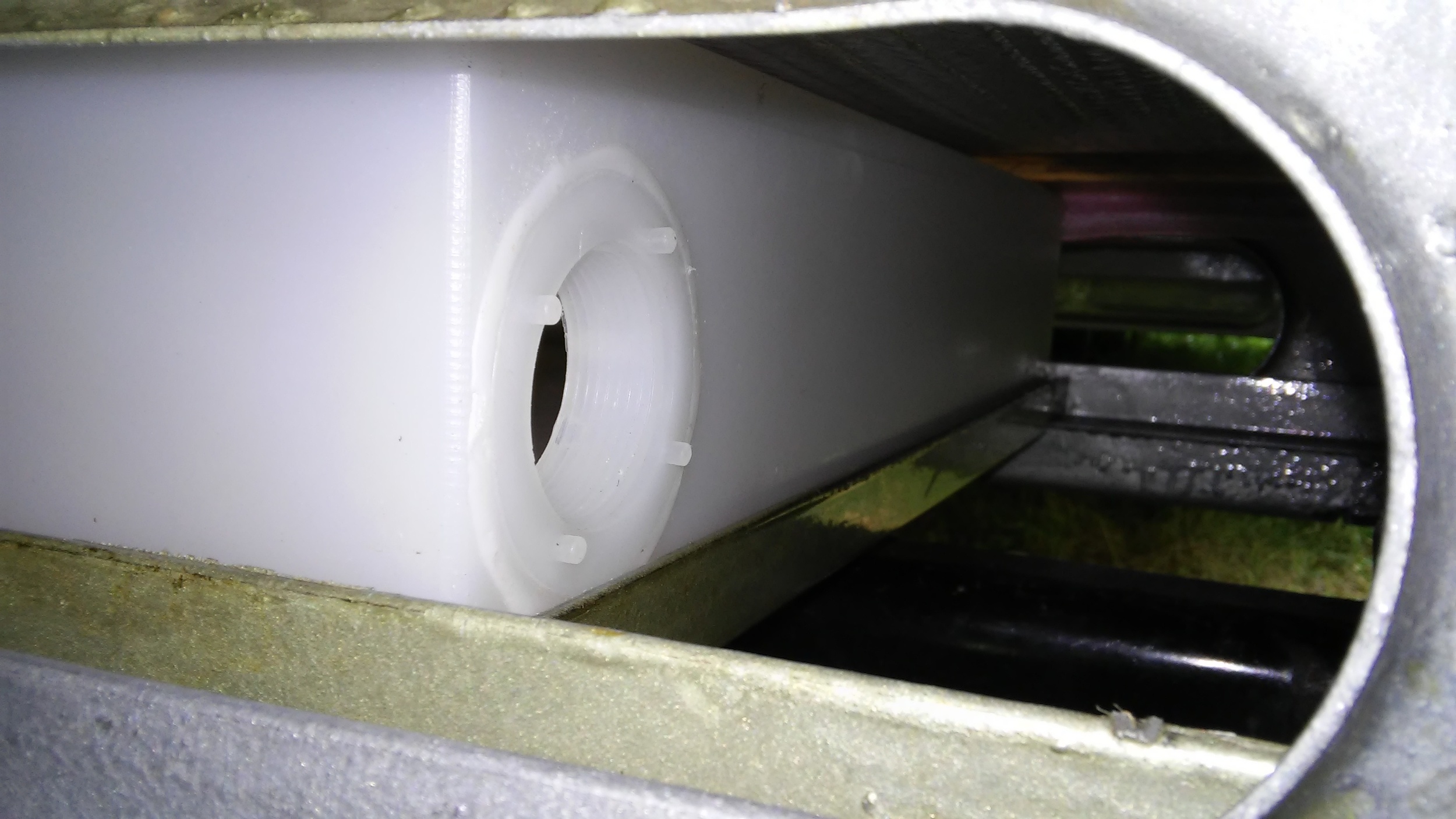

I welded a 1-1/2" steel angle to the bottom of the cross-member forward of the tank. I used the lip already present on the steel frame to support the street side, and I screwed a piece of 1-1/4" angle to the curb side of the plywood to prevent it from flexing. The aft side of the plywood is supported by another 1-1/2" steel angle, but this one is bolted into place so it's possible to remove in the future. I notched out four spots in the side of the plywood support to provide clearance for inserting the bolts, and cut a hole to accommodate the low point drain.

Once in, the tanks don't have much room for movement, but I shot a bunch of spray foam in the voids to help prevent things from shifting around, and to provide a little bit of insulation. I'm getting to like this Tite Foam product from Loctite. It's a lot more dense than your typical spray foam. That means a can doesn't go nearly as far, but it also makes me feel better about its capacity to stop air movement and hold its shape.