The Airstream originally had a gaucho, or sofa bed, up front. The couch cushion had a sheet of plywood attached to its underside, and the whole thing sat on top of an aluminum frame. This design makes for a cheap and lightweight piece of furniture with a good bit of storage underneath, but it makes for lousy sitting and sleeping.

I set out to make a durable, comfortable piece of furniture. This is really our only inside seating area aside from a small desk and ... ahem ... the toilet. So the couch needs to be comfortable. We also wanted to be able to convert it to a bed that's a bit more comfortable than a bunch of couch cushions sitting on the floor.

Some of these links are "affiliate links." If you decide to buy something based on our recommendation, it would be nice if you used the direct link from this page so that we can make a small commission for referring you (which doesn't cost you anything extra).

I researched common furniture dimensions here and here, and got pretty deep into a Youtube upholstery hole. I found a very useful set of videos for hand-tying springs produced by DIYUpholsterySupply.com, and ended up getting a bunch of my supplies from them.

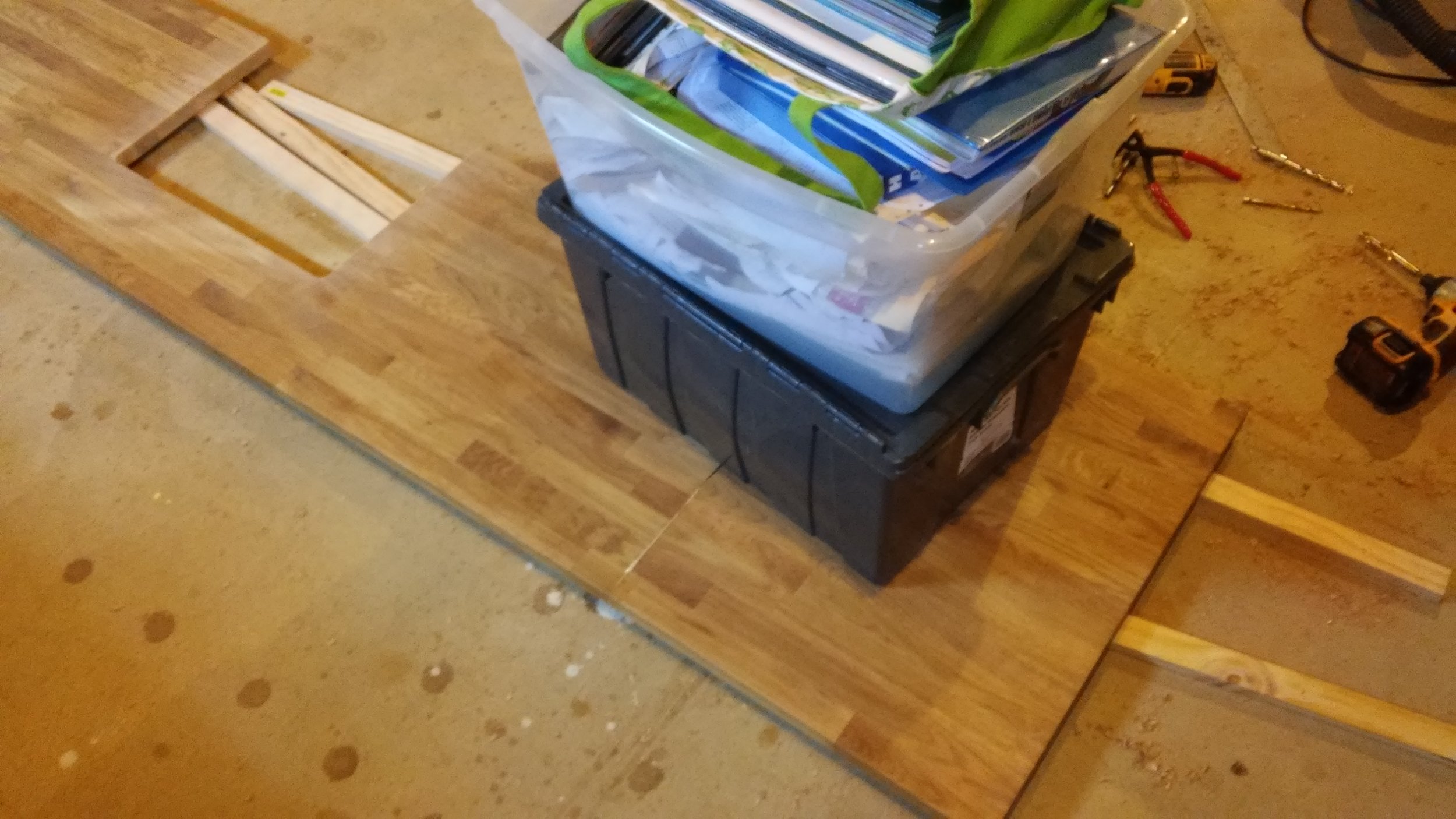

Since I want this furniture to last, I'm building the major load-bearing parts out of oak, and using dovetail joints for the higher stress areas. None of my local hardware stores carry dovetail saws, so I picked up this Japanese dovetail saw over at Amazon that I'm very happy with.

After a few practice joints, we're off and running. It's good to leave a little extra on either end of the joint, which you can trim flush with the dovetail saw or a block plane

After watching a bunch of YouTube videos of carpenters saying they do just fine marking their dovetails freehand, I tried it that way. Then I picked up this dovetail marking tool for $12. If you want to cut dovetails, just buy the marking tool. It'll easily pay for itself in frustration and wasted material.

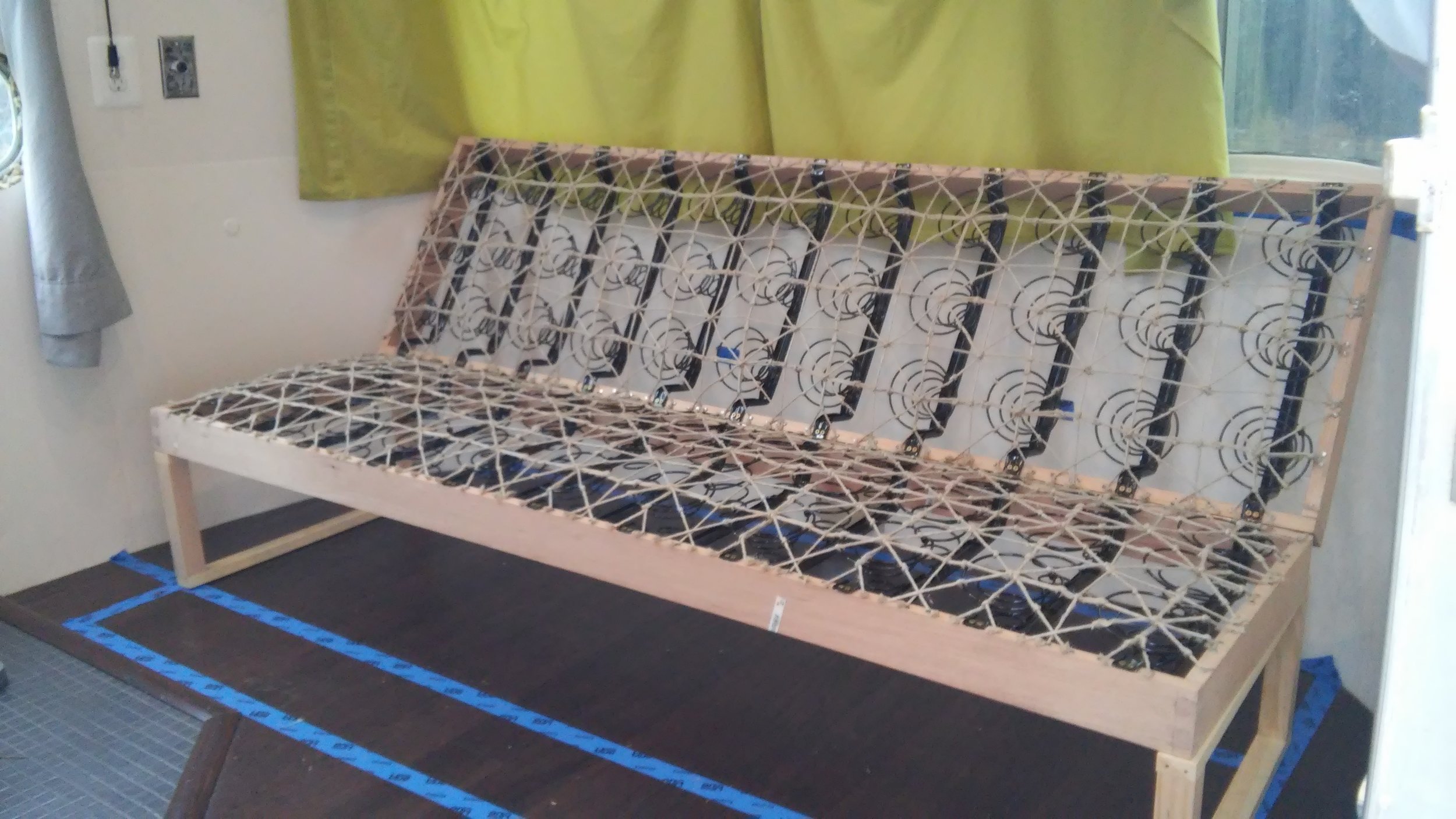

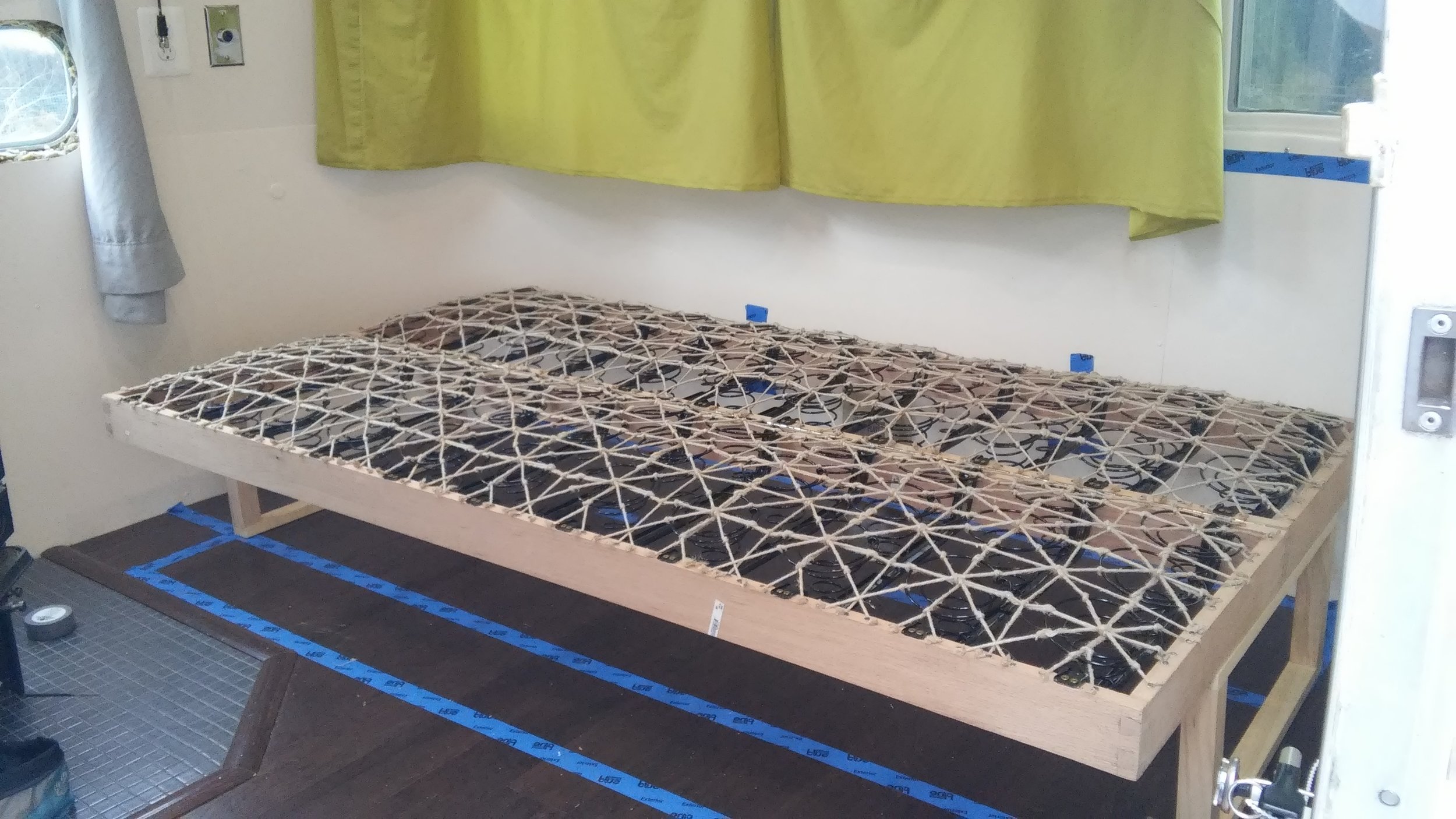

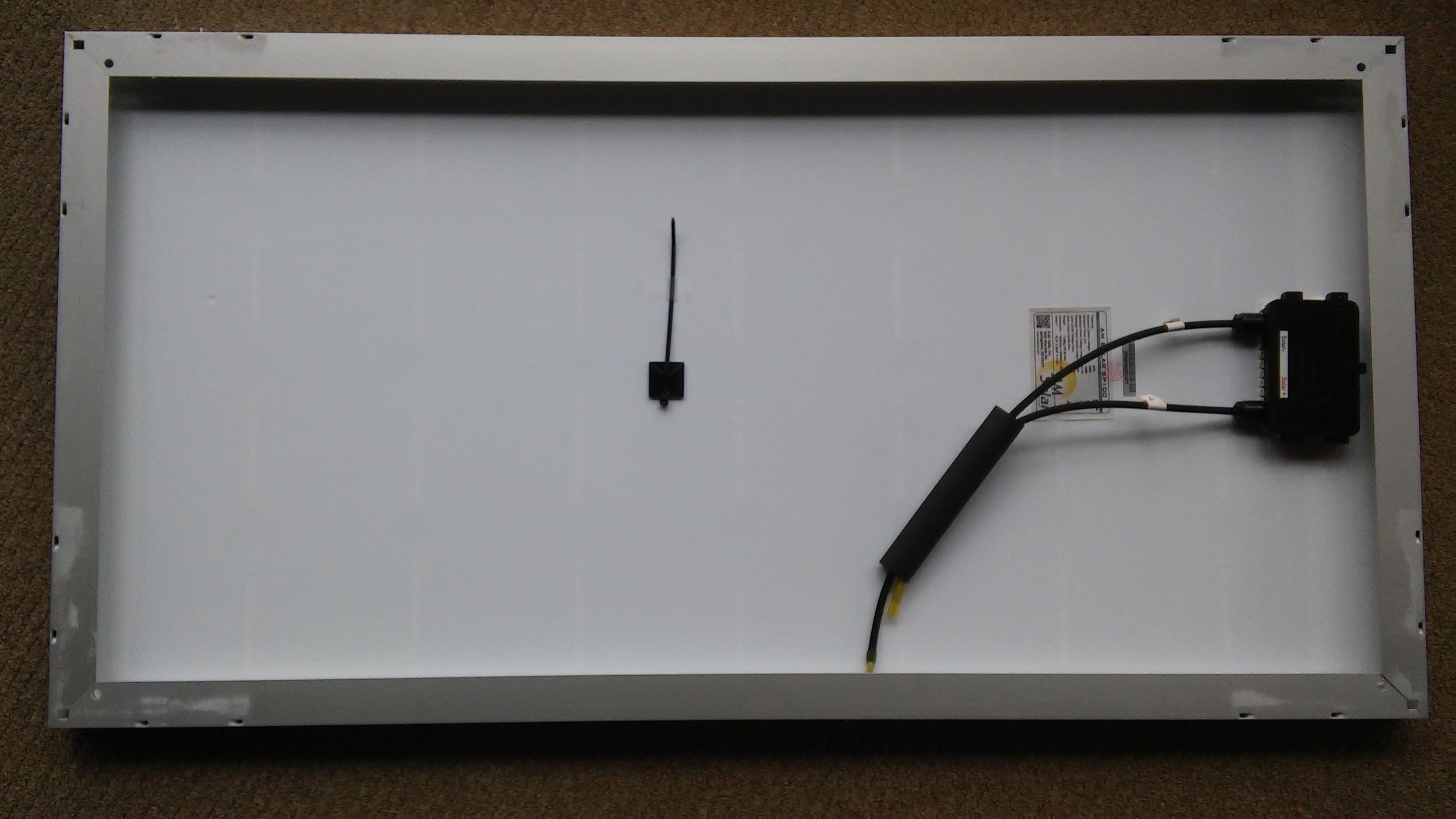

Frames are 6' long by 20" wide. 11 sets of 20" spring bars per frame made for fairly even spacing. Also got the big roll of Ruby Italian Spring Twine and a box of spring nails. About 300 knots per frame and we're in business.

I used a piano hinge to attach the two sides together and test fit the assembly. Lounge mode on the left, slumber party mode on the right.

I built the base and attached legs to the front of the seat. The legs will support the front of the seat when it's pulled out into a bed. I also started work on the arm rest, which will angle slightly outward. I considered building shelves or drawers into the space between the arm rest and the wall, but I think we're going to like the freestanding look better.

Next, I removed the piano hinge from the frames and started on covering them. First burlap to cover the springs, then 1" edge roll around the front and sides. I probably could have used 1-1/4" and got a little flatter seat. I did not put edge roll at the back of the seat or the bottom of the back because I don't want you to feel a lump behind your tailbone when sitting, or in the middle of the bed when laying down.

One layer of cotton batting with the edges tucked behind the edge roll, then another layer on top, hanging over the front. This will smooth out the back and seat a bit, and protect the fabric cover from the springs wearing through it. The fabric we chose is this charcoal colored linen blend.

Next, we reattached the piano hinge to the covered frames and reinstalled in the Airstream. The frames are fairly comfortable by themselves, but much better with a layer of cushions on the seat. I have the back angled at 26 degrees. Since the seat is horizontal (no backward angle), if the back reclines too much, you'll feel like you're sliding forward off the seat.

The seat cushion is going to be 4", but the back cushion is going to be pretty thin. Every inch of back cushion takes away an inch of seat depth, and 20" is on the shallow side for a couch seat anyway. If I didn't have to work around the wood stove and hearth, I might have used 21-1/2" bar springs for the seat to make it a little deeper. But the seat back is pretty comfortable even without a cushion, so we should be fine.

Luna approves of our progress.