Now that we have the interior skins in, I'm ready to complete the AC install. If you've been following closely, you may have noticed that I've already installed and removed the interior ceiling assembly a couple of times before this point. The AC unit works as long as the wires are plugged in, so I've been using it to heat the Airstream while I'm working on cold days.

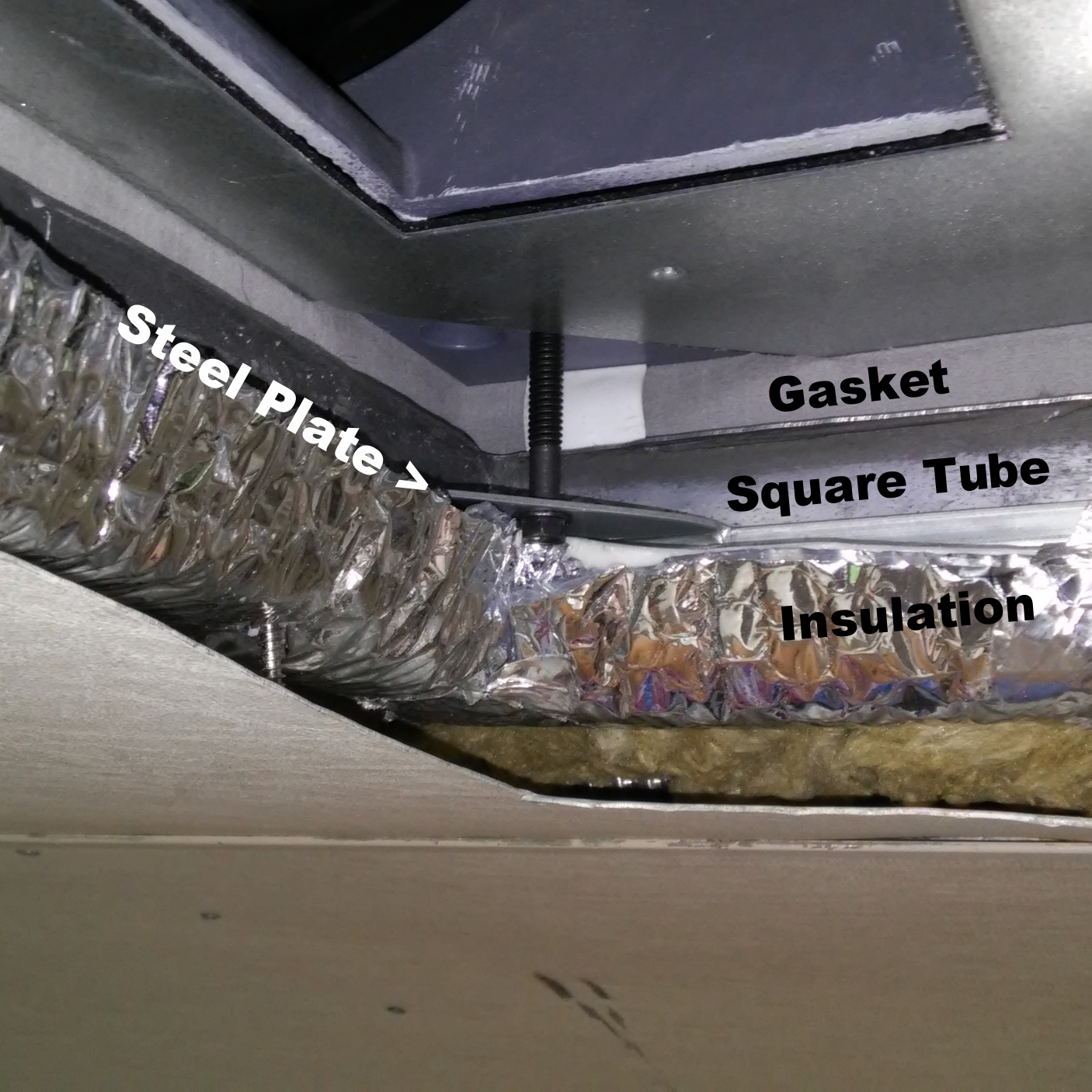

Before we get too far along here, let's review. Back in January, I added some 1" square aluminum tube around the perimeter of the roof opening for the AC to flatten out the area and provide something for the mounting hardware to grab.

Remember this photo from the previous Mach 8 Cub assembly post? This is the bottom of the rooftop AC unit. That foam gasket compresses against the roof opening to make a water tight seal. There is a white rectangular depth indicator at each corner to use as a reference point for the proper compression of the gasket.

Some of these links are "affiliate links." If you decide to buy something based on our recommendation, it would be nice if you used the direct link from this page so that we can make a small commission for referring you (which doesn't cost you anything extra).

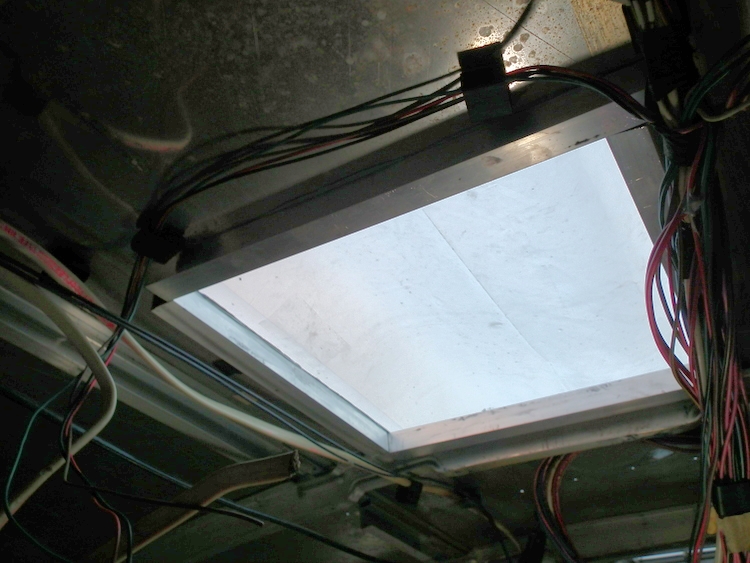

Now, here's the same view from the interior of the coach after the rooftop unit has been installed. There is a steel frame plate included that pinches the roof to the rooftop unit using four bolts -- one at each corner. You can just see the edge of the frame in these pictures at the head of the bolts. To attach the rooftop unit, you just have to get it in place and tighten down each of the four bolts until the white indicator just touches the roof. Simple. No need for sealant, and no need to double up on gaskets (I'm looking at you, Penguin).

As with any radial bolt pattern, you want to tighten these bolts evenly, together. So, get a little tension on one bolt, then put the same amount of tension on the bolt across from it, then do the other two before putting a little more tension on the first and repeat. Same as when you change a tire.

Technically, the steel plate is supposed to go below the ceiling inside the coach, not inside the ceiling. But I reinforced the opening with 1" square aluminum tube and not 1-1/2" tube to match the ceiling thickness, and I wanted to put the steel plate directly against the reinforcement for stability. So, I put the plate inside the ceiling and added some rigid foam insulation and a layer of Reflectix below to fill out the additional space. I'm happy with this choice because I was able to notch out the insulation to route the drain and electric through, rather than having to drill holes in the reinforcement tube. It does mean I need longer screws to attach the ceiling assembly because the ceiling assembly is meant to attach to the metal plate.

Now that we're all caught up, here's where we're at: interior ceiling assembly installation.

Now, before we permanently attach the duct to the ceiling assembly with the 3M VHB tape, I want to test-fit the rest of the ceiling assembly. That revealed that I need the inner part of the ceiling assembly to stand off the roof about 1/2" to accommodate the convex curve of the ceiling. So, I got some 2" #8 SS screws and some white high density rubber foam strips from the local orange box and installed it above the ceiling assembly like so:

3m VHB tape exposed, duct adhered, excess trimmed.

Lower ceiling assembly screwed in place. I had a heck of a time finding the correct holes. Remember, these screws attach to the steel plate that is now about 1" deep into my ceiling, so it takes some digging to get to the screw holes. Once the four screws are in, filters snap in, and covers snap on top. Temperature knob goes aft, fan speed goes forward. Make sure to use the knob that came in the heating coil box that says LOW HEAT instead of the one that came with the ceiling assembly that says LOW FAN twice.

Final result. Not bad.

Update for 2018: Coleman has released a new version 47201B876 Mach 8 Plus Cub rooftop unit. The Mach 8 Plus has a redesigned outdoor fan to reduce outside fan noise and improve heat transfer across the condenser coil. Find the new Mach 8 Plus Cub rooftop unit on Amazon here. The same ceiling assembly, heat kit, and condensate pump will fit.